Industrial Coffee Grinder vs. Personal Grinder: Key Differences Outlined

Industrial Coffee Grinder vs. Personal Grinder: Key Differences Outlined

Blog Article

Industrial Coffee Mill Guide: Increase Performance and Quality

In the competitive landscape of coffee production, choosing the best industrial coffee mill plays an essential duty in improving both efficiency and item high quality. Comprehending the subtleties of numerous mill types and vital features-- such as adjustable work settings and robust building-- can dramatically affect the final flavor profile of the coffee.

Comprehending Mill Kinds

When picking a commercial coffee mill, recognizing the various types readily available is essential for optimizing both taste extraction and operational efficiency. Both primary kinds of grinders are blade grinders and burr grinders. Blade mills use sharp blades that slice coffee beans into irregular sizes, resulting in uneven extraction and potentially unwanted tastes. While blade grinders are frequently more suitable and budget friendly for small operations, they are typically not advised for commercial usage.

Inevitably, picking the ideal sort of grinder is essential to maintaining top quality and efficiency in coffee production, making it vital for services to purchase premium burr grinders for optimal outcomes.

Key Functions to Consider

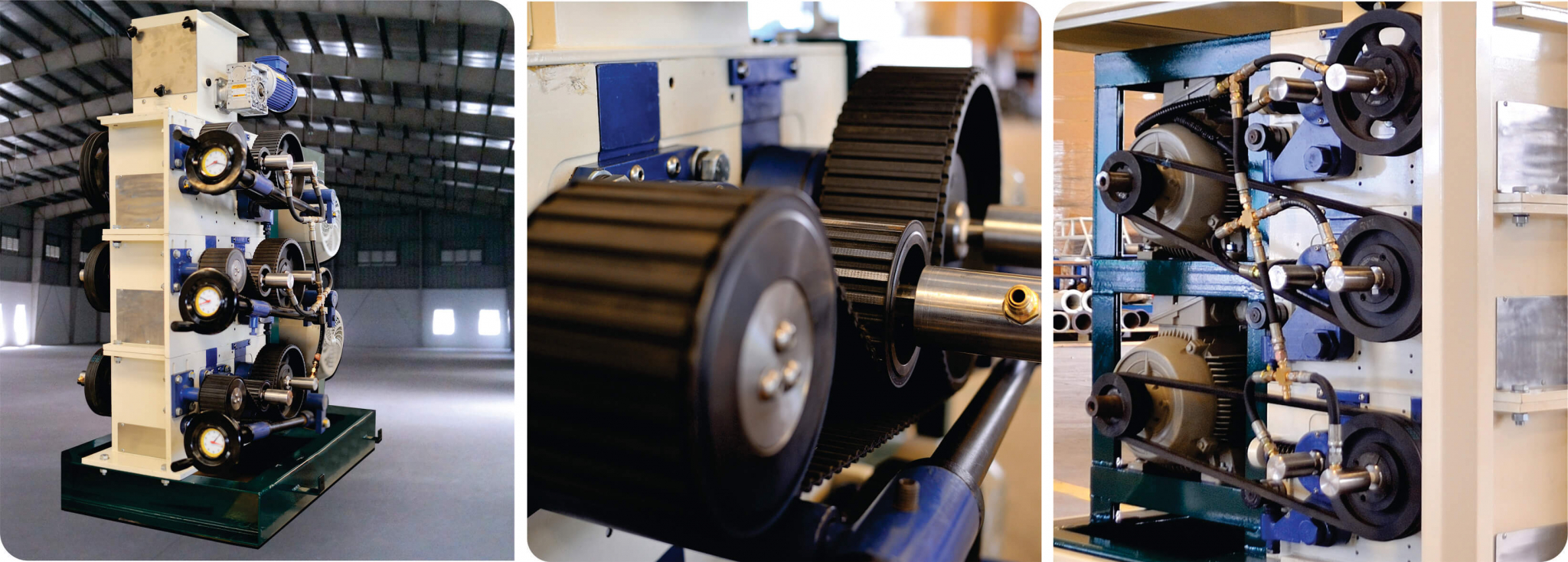

Choosing a commercial coffee mill needs mindful factor to consider of several key functions that can dramatically influence both performance and the total coffee experience. Among the primary aspects to examine is the grinding device. Burr mills are usually liked over blade mills, as they give a constant grind dimension, which is essential for optimum extraction and taste.

Another important function is the grinder's capability. A versatile grinder with several settings enables you to customize the work dimension to different developing methods, boosting the coffee's flavor profile.

The building material also plays a duty in resilience and maintenance. Stainless steel parts usually offer longevity and are less complicated to clean up, which is vital for keeping hygiene criteria. Finally, review the mill's sound degree, especially in a hectic coffee shop or production environment, where excessive sound can be disruptive. Purchasing a mill that stabilizes these functions can substantially enhance both operational efficiency and the top quality of the coffee offered.

Optimizing Grinding Refine

To attain the best results in coffee prep work, optimizing the grinding procedure is crucial. The grind size substantially influences removal, flavor, and total top quality of the brewed coffee.

Furthermore, checking the grinding rate can enhance the procedure. Slower grinding web link frequently produces much less warmth, protecting delicate flavors and scents. Alternatively, faster grinding might produce too much heat, adversely influencing the coffee's high quality.

Maintenance and Treatment Tips

Appropriate upkeep and treatment of commercial coffee mills are vital for making sure optimum performance and longevity. Normal cleaning is the foundation of maintenance; deposit buildup can impact taste and grinding efficiency. It is advisable to clean up the mill after each usage, cleaning down the outside Get More Info and getting rid of any coffee premises from the burrs.

In addition, evaluate the grinding burrs for wear and tear. Dull burrs can compromise grind uniformity, so they should be replaced as necessary. Industrial Coffee Grinder. Occasionally adjusting the mill browse around here is likewise vital, as this preserves the preferred work size for various developing methods

Lubrication of relocating components ought to be done according to the maker's specs, as this minimizes friction and extends the life of the equipment. It is important to utilize food-grade lubricating substances to make certain security and compliance with wellness guidelines.

Lastly, maintain the grinder in a completely dry and stable atmosphere to avoid corrosion and corrosion. By adhering to these upkeep and treatment tips, drivers can enhance the performance of their commercial coffee mills while making sure premium output and extended functional life.

Return on Investment Analysis

Evaluating the return on financial investment (ROI) for industrial coffee mills is essential for companies looking for to optimize their coffee production abilities. A complete ROI evaluation assists determine the monetary practicality of investing in top notch grinders, enabling companies to consider the initial costs versus potential gains.

To carry out an extensive ROI analysis, businesses should consider numerous crucial variables. Assess the acquisition price of the mill, consisting of setup and any needed modifications to existing infrastructure. Next off, calculate functional expenses, including power consumption, maintenance expenses, and labor performance renovations. High-performance grinders typically bring about decreased grinding time and boosted throughput, which can dramatically enhance efficiency.

Furthermore, consider the influence on product top quality. Industrial Coffee Grinder. Superior mills yield an even more constant grind dimension, which can boost taste accounts and client contentment, inevitably driving sales. By enhancing the high quality of the end product, organizations can validate greater pricing, leading to raised revenue

Verdict

In summary, a commercial coffee mill plays a pivotal function in improving both effectiveness and product top quality within coffee manufacturing. By selecting high-quality burr mills geared up with crucial features such as flexible work settings and durable building, businesses can guarantee ideal flavor removal. Moreover, routine maintenance is vital for maintaining grinder efficiency and maximizing customer complete satisfaction. Ultimately, the critical investment in a trustworthy grinder adds dramatically to boosted income and competitiveness in the coffee sector.

In the affordable landscape of coffee manufacturing, selecting the ideal industrial coffee grinder plays an essential duty in improving both efficiency and item quality. The two key types of mills are blade grinders and burr mills. Within the burr grinder classification, there are level burr grinders and cone-shaped burr grinders, each with its benefits. Burr grinders are normally liked over blade grinders, as they offer a constant work dimension, which is crucial for optimum removal and taste.

In recap, an industrial coffee mill plays a crucial function in enhancing both performance and item high quality within coffee manufacturing.

Report this page